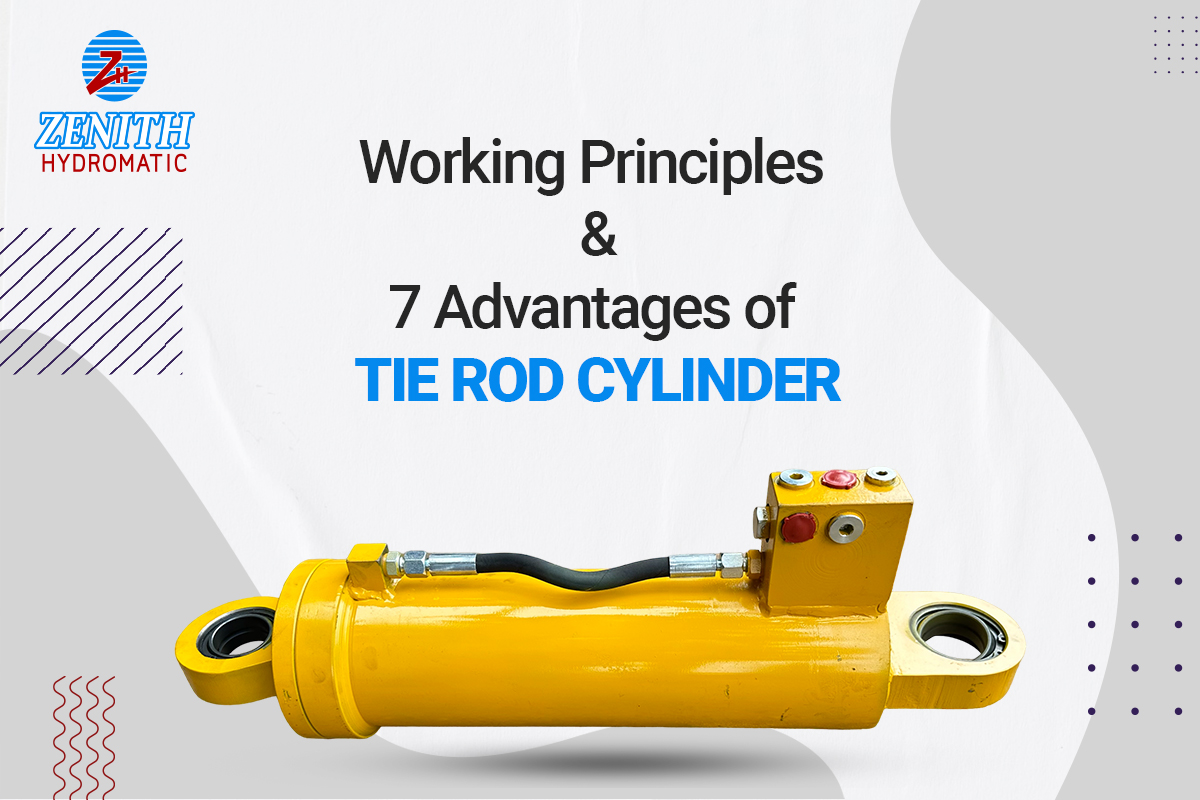

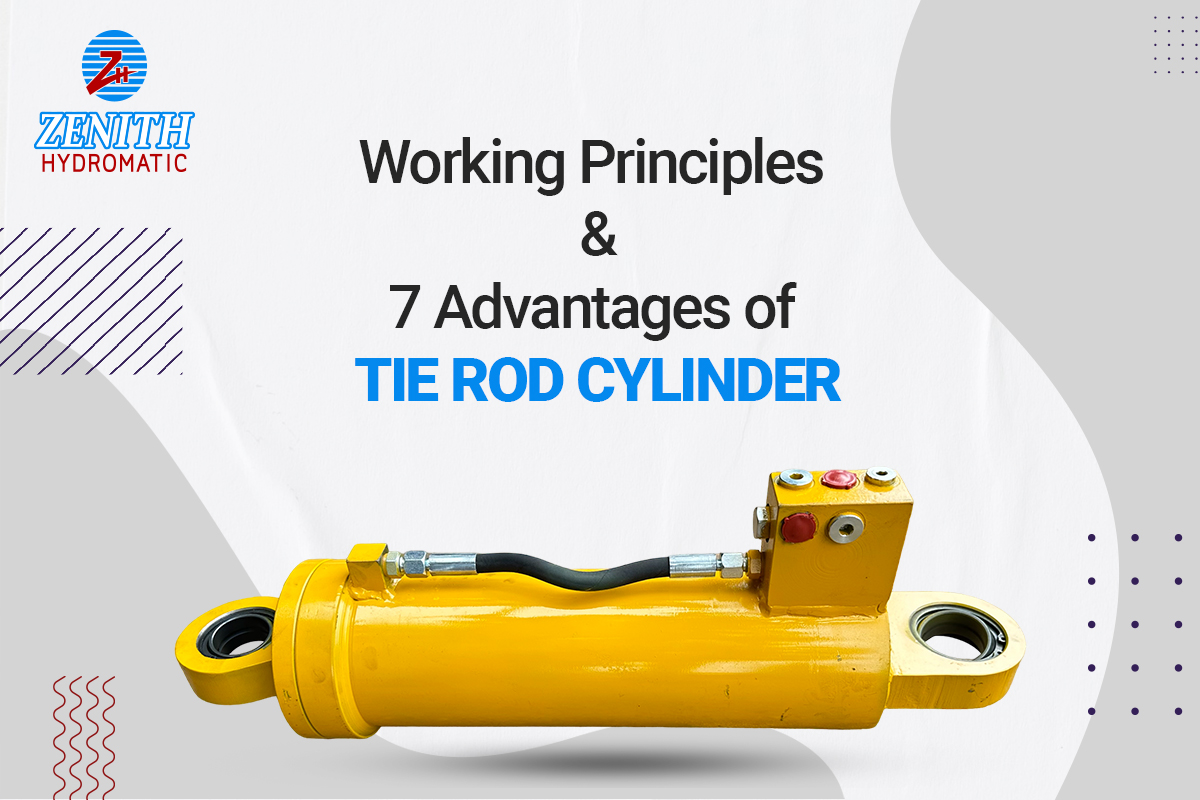

In the busy world of India’s factories, the tie rod hydraulic cylinder is a key player. It’s a part of many machines, doing all sorts of jobs, big and small. This cylinder works by using liquid power to move things. It’s a smart way to get work done, from lifting heavy stuff to helping in making things with precision. For factory owners and industry workers, knowing the ins and outs of this cylinder is key to optimizing operations.

This blog will take you through what makes the tie rod hydraulic cylinder so special and useful. Whether it’s enhancing machine performance or ensuring reliability in demanding tasks, understanding this tool is invaluable. Thus, let’s dive in and learn about this powerful tool that keeps machines running smoothly.

What are Tie-rod Cylinders?

A tie rod cylinder is constructed with high-strength threaded steel rods that secure the end caps to the cylinder barrel. These cylinders often have static seals to stop leakage between the barrel and end-cap interface. Large, industrial cylinders can have up to twenty tie rods to sustain extreme force, whereas small cylinders typically have four.

Hydraulic tie rod cylinders are praised for their small size and are primarily utilized in industrial settings. Many are constructed to NFPA standards, allowing for simple disassembly in the event of a malfunction, and the majority do not exceed 3,000 psi.

How a Tie-rod Cylinder Functions

The tie rod cylinder is made up of a piston, cylinder, seals, connecting rods, and connectors. When hydraulic oil enters the cylinder, it moves the piston forward or backwards. The movement of the piston causes the connecting rods and connecting elements to move together. This results in mechanical motion. When the hydraulic oil is drained from the cylinder, the piston returns to its original position, completing the operating cycle.

Advantages of Tie-Rod Cylinder

Tie-rod cylinders are a popular choice in various industries for their significant advantages. Let’s delve into these benefits in detail, ensuring clarity and simplicity in explanation.

1. High Durability and Strength

Tie-rod cylinders are built tough. They’re designed to withstand high pressures and heavy use without wearing out quickly. This means they can handle tough jobs for a long time. Their strength comes from the tie rods that hold the cylinder together securely, making sure it can take on heavy loads without a problem.

2. Easy Maintenance

What’s great about tie-rod cylinders is that they’re easy to look after. If something goes wrong or parts need to be checked, you can easily take the cylinder apart because of the way it’s put together with tie rods. This makes fixing or replacing parts straightforward, saving you time and effort.

3. Versatility

Tie-rod cylinders can be used for a wide range of tasks. They come in different sizes and can be adapted to various pressures and environments. This means whatever your specific need, there’s likely a tie-rod cylinder that’s perfect for the job. It’s this versatility that makes them a go-to option in many different fields.

4. Enhanced Safety

Using tie-rod cylinders also means enhanced safety. Their reliable performance and strong build reduce the risk of accidents caused by equipment failure. Knowing that your machinery is less likely to break down unexpectedly not only keeps operations smooth but also keeps everyone around safer.

5. Cost-Effectiveness

Despite their high quality, tie-rod cylinders are a cost-effective solution. Their durability means you won’t have to replace them often, saving money in the long run. Plus, because they’re easy to maintain, you’ll spend less on repairs. This makes tie-rod cylinders a smart financial choice for businesses.

6. Customization Options

Another advantage is the ability to customize tie-rod cylinders to meet specific needs. Whether you need a certain size, pressure capacity, or material, manufacturers can often make adjustments to fit your requirements. This flexibility ensures that you get exactly what you need for your particular application.

7. Easy to Install

Lastly, tie-rod cylinders are designed for easy installation. Their structure allows them to be quickly fitted into machinery with minimal hassle. This means less downtime when setting up new equipment or replacing cylinders, helping to keep projects on schedule.

Conclusion

Tie rod hydraulic cylinders represent a fusion of simplicity, strength, and versatility. This makes them indispensable in India’s industrial landscape. Their robust design, coupled with the ability to withstand high pressures and ease of maintenance, positions them as a top choice for business owners looking to enhance efficiency and reliability in their operations.

If you are looking for the best tie rod hydraulic cylinder manufacturers in India, look no further than Zenith. We are the leading hydraulic cylinder manufacturer in India. Also, our high-quality tie-rod hydraulic cylinders are reasonably priced!

Call us at +91 8200534779 to discuss your needs, or visit our website!

Get in touch now!