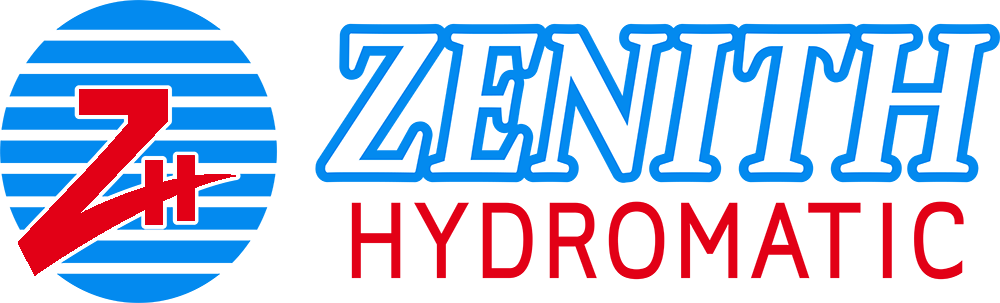

Zenith Hydromatic has been designing and building modern Compressor and force feed lubrication system as well as equipment that serve the in-plant manufacturing industry since 1994 under the guidance of its founder Mr. Amrut Patel Who had an experience of nearly 35 years in the field

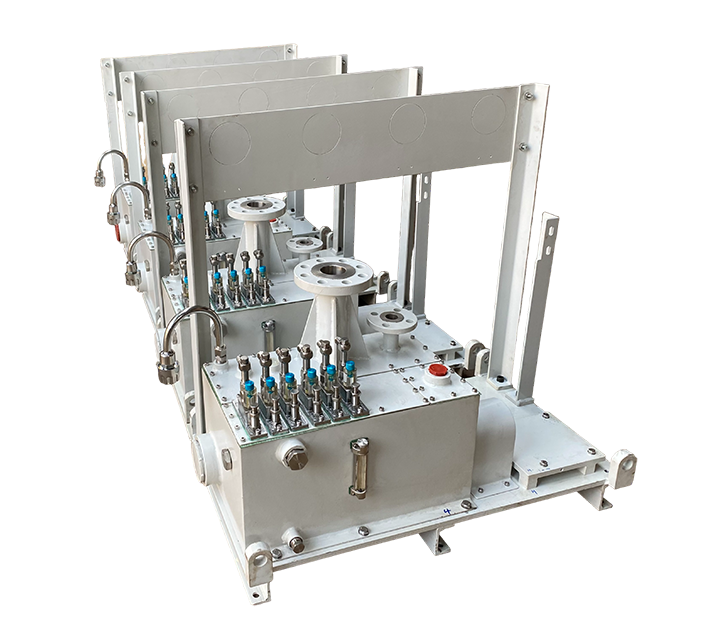

Enhanced Force-Feed Lubrication

Compressor lubrication equipment for markets such as gas pipeline booster stations, refineries, CNG stations, and more. Our newest generation of automatic lubrication equipment is the result of years of collaboration with our customers and partners to engineer high-quality, reliable Compressor and force feed lubrication systems that stand above the rest.

Auto Lubrication Systems to increase longevity and reliability of compressor cylinders, rings, rods and packing material in any environment.

Zenith hydromatic™ Supply OEM Lube Boxes and Pumps to Respective brands.

- Ingersoll Rand

- Dresser-Rand

- Kirlosker Pneumatic

- Jyotech

- Bharat Pumps & Compressors Limited

- GOMA

- Hironisha

- C&B pumps & Compressor

- Burckhadrt

- Comptech

- L&T – Mumbai

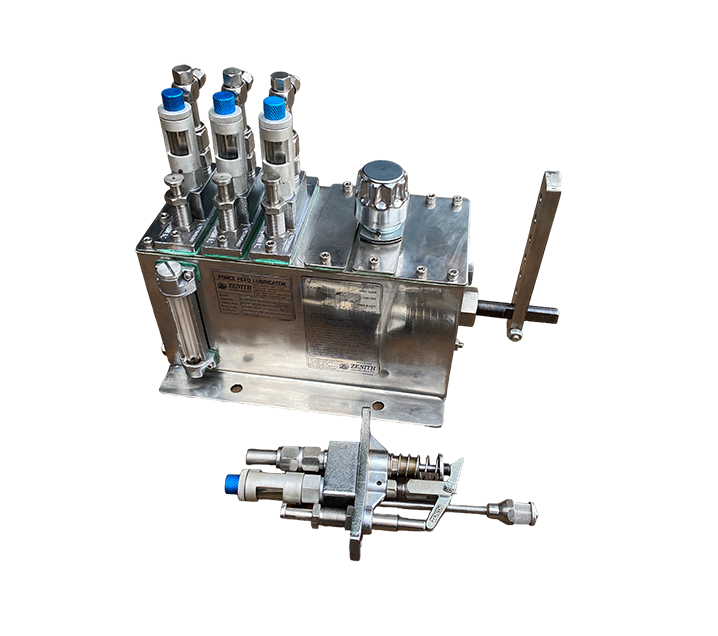

Zenith Hydromatic Builds Replacement Lube Boxes and Pumps to Retrofit

- Graco

- Lubriquip

- Manzel

- Lincoln

- Premier

- Coulthard

- CPI

* All trademark names are the property of their respective companies and not associated with Zenith hydromatic.

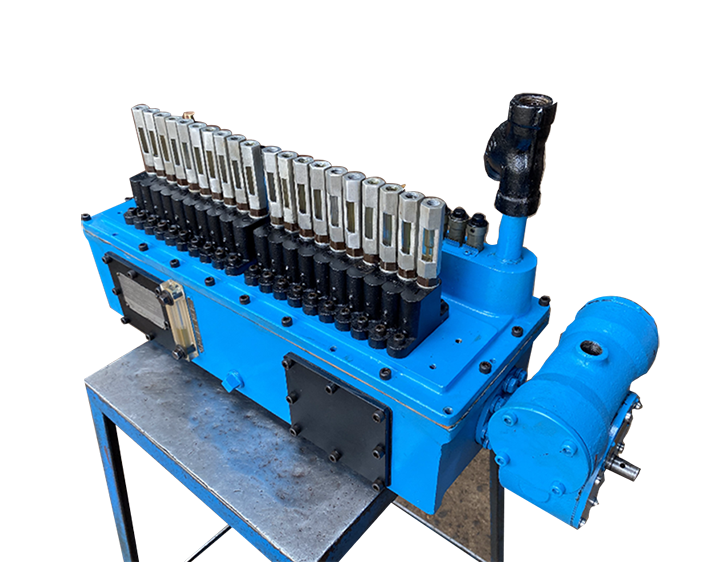

There are two main operational methods used when providing lubrication.

- Pump-to-Point – directly to each delivery point from each individual pump unit.

- Series Progressive – via a divider valve system that cycles output to each lubrication point.

- Combined – a combination of both systems above.

Each of these methods has pros and cons and we would be delighted to discuss the merits of both to ensure you have the best possible designed compressor and force feed lubrication system for the task needed.