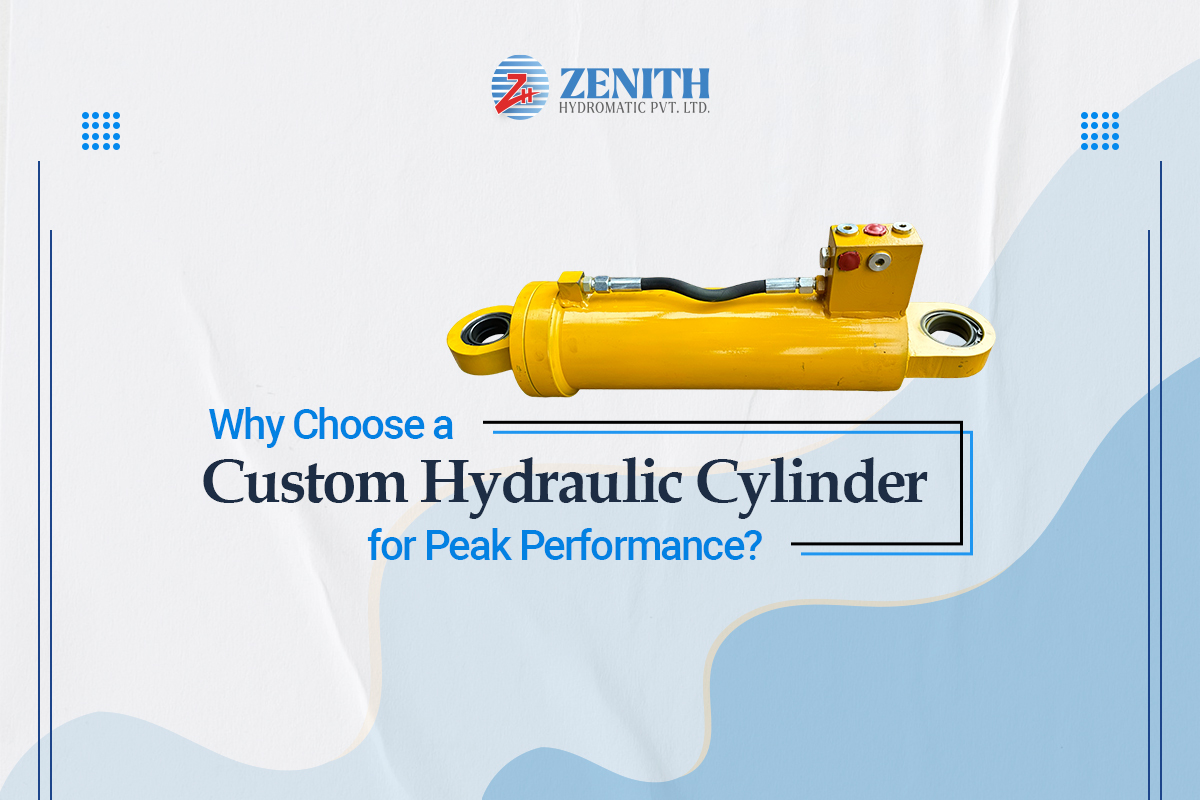

In industries like construction, agriculture, mining, and material handling, off-the-shelf hydraulic cylinders often fall short. That’s where custom hydraulic cylinders come in, engineered with precision to meet unique applications and demanding conditions. This guide explores why custom models outshine generic options, how they benefit your operations, and when they’re the smart investment, especially from trusted manufacturers like Zenith Hydromatic.

1. Why Custom Works Better than One-Size-Fits-All

Ready-made cylinders suit average setups—but what if your requirements don’t fit the “average”? A bespoke hydraulic cylinder design is built to match your exact operational needs:

- Optimised dimensions: tube diameter and stroke length align perfectly with your machine’s movement

- Mounting modes: custom eyes, clevises, flanges, or trunnions that drop right in, eliminating adapters

- Tailored materials and seals: stainless steel for corrosion, high-temp seals for heat — whatever your environment demands

The result? A smooth-running system that doesn’t fight its cylinders, leading to better performance, higher uptime, and fewer surprises.

2. Built to Handle the Toughest Demands

Maybe your application puts sideways force on the cylinder, or you’re using it in dusty, abrasive, or wet environments. Standard designs can suffer from side-loading, premature seal wear, or corrosion. Custom units solve those problems by:

- Using thicker walls and reinforced rod sizes for sturdiness

- Fitting heavy-duty seals that resist abrasion and pressure spikes

- Adding hard-chrome or zinc plating for corrosion resistance

Your unique conditions are taken into account from day one, not after failures start cropping up.

3. Built-In ROI That Pays Off

Yes, custom variants often cost more upfront, but they’re investments that pay dividends:

- Less frequent breakdowns and part failures

- Reduced energy loss through optimized designs

- Minimal downtime, translates to less production lost

- Longer service intervals and fewer emergency repairs

Over the full lifecycle, the custom route is often cheaper and less stressful than patching together standard parts or waiting for replacements.

4. A Partner You Can Rely On

Companies like Zenith Hydromatic don’t just sell cylinders— they collaborate through the entire process:

- Discovery Consultation

Clients describe the load profile, environment, mounting layout, and usage rhythm. - Technical Design Review

Engineers fine-tune bore size, stroke, rod thickness, and sealing systems. - Prototype & Validation

Early models undergo test rigs and pressure cycles to prove performance under expected conditions. - Fast, Reliable Delivery

With efficient production workflows, most custom cylinders ship within 4–6 weeks. - Post-installation Support

Installation guidance, maintenance training, and repair services ensure the cylinder delivers as promised.

5. Real-World Success Examples

- A factory retrofitted cables with larger-diameter cylinders to reduce energy usage on heavy loads, saving 15% in electricity costs within a year.

- A forestry operation moved to stainless steel rods and heavy seals to withstand constant moisture and sawdust—and cut downtime by 40%.

- A recycling plant integrated cylinders with built-in position sensors for automated sorting, improving accuracy and throughput dramatically.

Ready to Reinvent Your Hydraulic System?

If you’re frustrated with short-lived cylinders, poor fit, or downtime, it’s time to explore a tailored solution. At Zenith Hydromatic, our engineers build cylinders that match your technical needs and your workflow, right down to the last bolt.

Talk to us today for a free discovery session and custom quote:

📞 +91 8200534779

✉️ sales@zenithhydromatic.com

Let’s build something that works better and lasts longer—for your machines and your team.

FAQs: What Others Commonly Ask

Q1: How much does a custom cylinder cost vs a standard one?

They start higher, but long-term savings on maintenance, downtime, and parts replacement typically outweigh the initial cost.

Q2: How long does it take to get one built?

Once approved, delivery typically takes 4–6 weeks, with fast-track options often available for repeat orders.

Q3: Can I add smart features like sensors?

Yes. Position sensors, proximity switches, and ports for control valves can be included from the design phase.

Q4: Is a custom cylinder harder to maintain?

Not at all. In fact, replacing standard wear parts is easier since everything is designed to fit perfectly from the start.