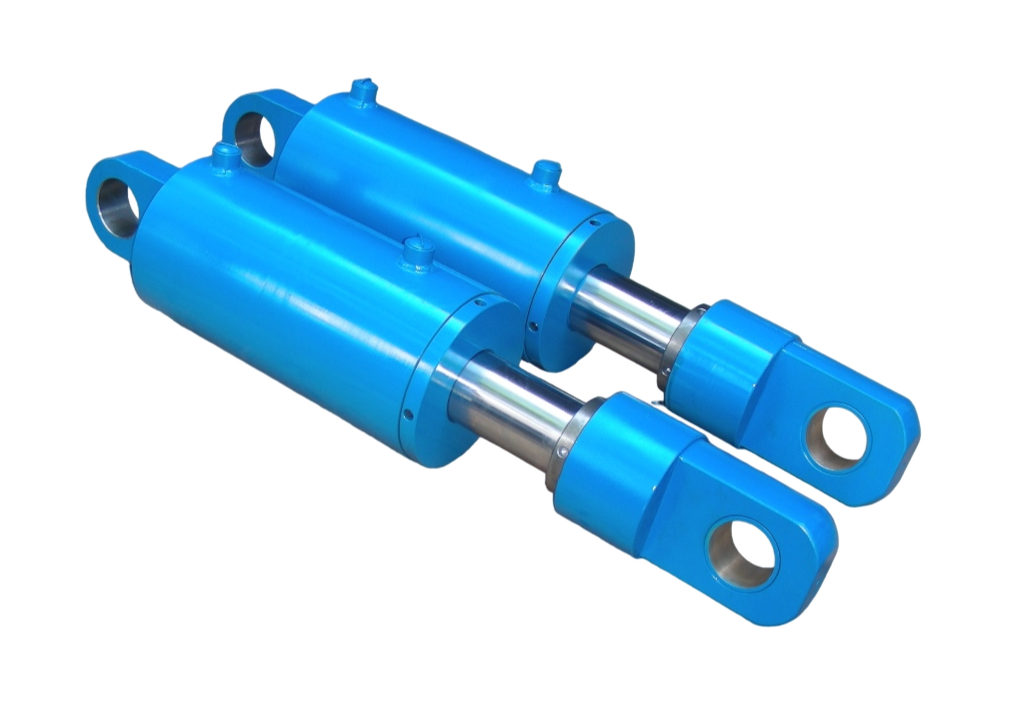

Features of the Welded Hydraulic Cylinders

- Customizable Bore Size, Stroke Length, and Lifting Capacity: Specifically tailored to meet diverse operational requirements.

- Versatile Mounting Configuration Options: Adaptable to various machine designs for optimal compatibility and performance.

- Threaded/Bolted Gland and Endcap Options: Enhances cylinder durability and ensures a secure, robust construction.

- Counterbalance and Pilot Operated Check Valves: Incorporated for superior safety and precise control in operations.

- Flexible Porting Options (ORB, NPT, C61) and Locations: Customizable to fit specific hydraulic system configurations.

- Custom Paint Specification: Personalize the appearance to match your machinery, maintaining aesthetic consistency.

- Designed for High-Pressure, High-Cycle, and High-Vibration Applications: Ensures reliability and longevity under demanding conditions.

- Compact and Aesthetically Pleasing Design: Balances functional efficiency with an attractive appearance.

- Repairable Construction: Engineered to be maintainable, promoting sustainability and extended service life.

Get A Quote

Advantages of Welded Hydraulic Cylinders

The following are the benefits of Zenith’s Welded Hydraulic Cylinders.

- Customizable Design: Offers flexibility beyond standard configurations to meet specific application requirements.

- Design Versatility: Adapts easily to varied industrial needs with options for integral valve incorporation and welded fluid lines.

- Elimination of Threaded Connections: Integrated valves and welded lines reduce the need for additional connections, enhancing reliability.

- Flexible Porting: Allows for adaptable port sizes and locations to fit diverse hydraulic systems.

- Repairable Construction: Designed for ease of maintenance, ensuring longevity and consistent performance.

- Compact and Aesthetic Design: Achieves a balance between sleek appearance and functional efficiency.

- High Integrity in Tough Conditions: Excellently suited for high-pressure, cyclic, and vibrational environments.

- Enhanced Safety Features: Built-in safety mechanisms for secure and controlled operations.

- Eco-Friendly Options: Supports sustainable practices with repairable and durable components.

These benefits highlight Zenith Hydromatics’ commitment to delivering high-quality, durable, and efficient welded hydraulic cylinders, tailored for challenging industrial applications.

Get A Quote

Applications of Custom Hydraulic Cylinder with Welded Design

Welded design hydraulic cylinders from Zenith Hydromatics find their applications in a variety of industries, each requiring the reliability and efficiency that our products guarantee. Here are five major applications:

- Food Industry: Our cylinders play a key role in food processing and packaging machines, offering controlled and precise movements that ensure efficiency and maintain hygiene standards, which are critical in this sector.

- Construction Projects: These hydraulic cylinders are essential in construction machinery such as excavators, cranes, backhoes and bulldozers. They provide the necessary power for lifting, digging, and moving materials, thereby contributing significantly to the

efficiency of construction operations.

- Waste Management: In the domain of waste management, our cylinders are used in compactors and recycling equipment. They handle large volumes of waste effectively, making them indispensable for modern waste management solutions.

- Metal Fabrication: Our hydraulic cylinders are crucial in the metal fabrication industry. They provide the high-strength force required for bending, shaping, and cutting metals, ensuring precision and reliability in various metalworking processes.

- Agricultural Machinery: In the agricultural sector, these cylinders are used in tractors, combines, and harvesters. They play a crucial role in enabling the heavy lifting and precise movements required in modern farming techniques.

- Material Handling: In warehouses and logistics centres, our welded hydraulic cylinders are employed in forklifts, pallet jacks, and

conveyor systems. They ensure smooth operation and handling of heavy loads with precision.

- Automotive Industry: These cylinders are also used in automotive manufacturing, particularly in assembly lines and lifting systems. They provide the high-pressure force needed for pressing, bending, and shaping automotive parts.

- Renewable Energy Sector: In wind turbines and solar panel installations, our hydraulic cylinders are used for their maintenance and operation, ensuring the alignment and positioning of large, heavy components.