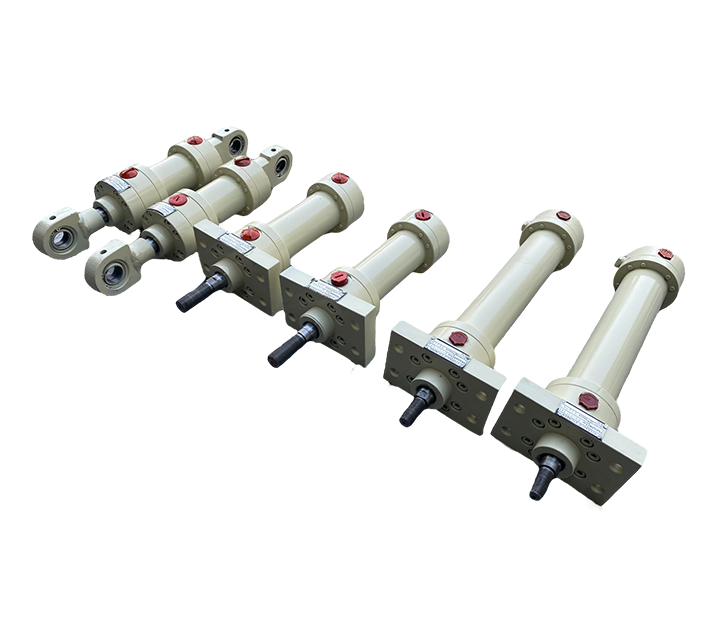

Features of the Mill Duty Hydraulic Cylinder

Below are the amazing features of Zenith’s advanced “Mill Duty Hydraulic Cylinders.

- Robust, Heavy-Duty Designs: Engineered to withstand harsh industrial environments.

- Bolted Head and End Cap: Ensures enhanced security and durability.

- Easily Serviced: Designed for quick and efficient maintenance.

- Reliable Performance: Consistently operates under strenuous conditions.

- Extended Wear, Long Service Life: Built to last, even in tough applications.

- High Safety Standards: Complies with rigorous safety protocols.

Get A Quote

Advantages or Benefits of Mill Duty Hydraulic Cylinders

Zenith Hydromatics’ Mill Duty Hydraulic Cylinder offer a multitude of benefits tailored to demanding industrial applications:

- Enhanced Durability with Chrome Bore: The optional chrome bore provides superior resistance to wear and corrosion, extending the cylinder’s lifespan even in harsh environments.

- Customizable Cushioning: Adjustable cushions allow for tailored end-of-stroke deceleration, enhancing control and reducing impact.

- Efficient Air Bleed System: Air bleeds facilitate the removal of entrapped air, ensuring smoother and more reliable cylinder operation.

- Specialized Material Options: Availability of special materials and plating options to withstand diverse operational conditions,

increasing resistance to environmental challenges.

- High-Temperature Seal Options: Specially designed seals are available for high-temperature applications, maintaining integrity and performance in extreme heat.

- Integrated Valve Technology: Streamlines system design by incorporating valve functions, reducing complexity and potential leak points.

- Accurate Position Feedback: Equipped with linear displacement transducers for precise position monitoring, crucial for automation and control.

- Proximity Switches for Enhanced Control: Allow for precise operation monitoring, contributing to safer and more efficient processes.

- Versatile Mounting Options: Dual mounting styles cater to different installation requirements, offering flexibility in application.

These advantages position Zenith Hydromatics’ Mill Duty Hydraulic Cylinder as the go-to choice for industries requiring robust, reliable, and efficient hydraulic solutions.

Get A Quote

Applications of Mill Duty Hydraulic Cylinders

Zenith Hydromatics’ Mill Duty Hydraulic Cylinders are engineered to excel in a range of demanding industrial applications:

- Steel Mills: In the heart of steel production, these cylinders are pivotal for heavy-duty lifting, handling, and processing tasks, ensuring continuous, reliable operation in the challenging environments of steel mills.

- Foundries: They play a crucial role in moulding and casting processes, where precision and durability are paramount for handling high-temperature materials and rugged conditions.

- Mining Applications: Essential in the mining sector, these cylinders facilitate excavation, ore processing, and handling of heavy equipment, proving their resilience and reliability in one of the harshest industrial environments.

- Oil and Gas Drilling: In the oil and gas industry, these cylinders are key components in drilling rigs and other extraction equipment, providing the strength and stability needed for efficient and safe operations.

- Industrial Machinery: Their versatility makes them suitable for a wide range of industrial machinery applications, where they provide the necessary force and control for various manufacturing and processing tasks.

These applications underscore the adaptability, robustness, and efficiency of Zenith Hydromatics’ Mill Duty Hydraulic Cylinder, making them indispensable in industries where performance under pressure is not just a requirement, but a necessity.